Precision Screw Machine Products

Alpha Grainger Manufacturing, Inc. • 20 Discovery Way • Franklin, Massachusetts 02038 • 508-520-4005

About: Letter From The CTO

The Pursuit Of Speed

From its founding in 1973, Jake Grainger has run the show at Alpha Grainger.

Now more than ever, he embraces his role as Chief Technology Officer as the business and the industry continue to evolve.

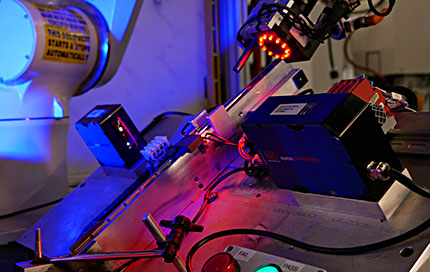

Every year, Alpha Grainger Manufacturing invests millions of dollars in new technology. New machines, new capabilities, new processes and the training for its employees to capitalize on these investments.

For Jake Grainger, it all boils down to the pursuit of speed. He craves efficiency and he’s extremely proud of the technological legacy the company has built over the last 45 years. “I look at where the industry has come since we started here in 1973 and it’s amazing what we’re now able to machine here at our facility. Technology has helped us compete and I firmly believe it’s what will keep us competitive for years to come,” Grainger explains. “Complex parts are what customers need help with and we’ve always fought to stay at the forefront of producing them. Its what customers know us for and it’s why we’re still a valuable partner for them today.”

His employees have noticed, too. “It’s been so great to come to the Alpha Grainger environment, where they make the investment in all the technology you could ever need to produce parts for all the most competitive companies,” says Mike Esposito, who’s been with the company for a few years. “Every department is empowered by management to utilize the latest machining related technology from plunge and wire EDM, to metrology and in-house tool manufacturing. Everyone on the floor is unified behind minimizing cycle times. It’s awesome. Anything we need, Jake is always willing to listen. The whole organization does!”

At 70 years old, Jake Grainger shows no signs of slowing down. “We put 2,300 solar panels on our roof to help pay for our power output. We’ve invested in government-grade data security. And, we have continued to invest in training our people to understand how everything works together. Business moves faster every day, and we couldn’t be more excited about everything we’re doing to stay ahead of the curve!”

CNC Swiss Machining

Multi-Spindle Screw Machining

Rotary Transfer Turned Parts

Site Design: Design-2-Part Web Design